Pavement

- Publication no: AP-R663-21

- ISBN: 978-1-922700-18-6

- Published: 16 November 2021

- PDF (free) Download

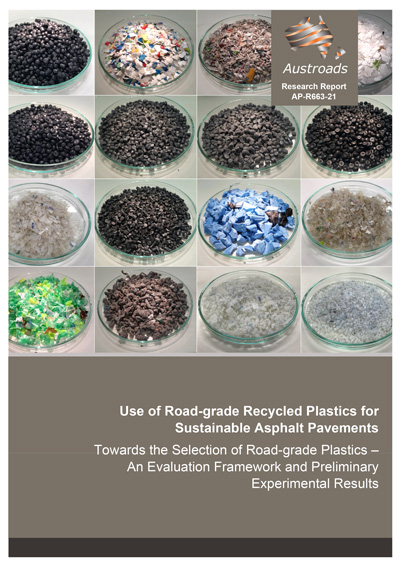

This report provides a comprehensive overview of the initial development of various testing frameworks for the characterisation of road-grade recycled plastic, the incorporation of recycled plastics in bitumen and asphalt via various methods (wet, dry, and mixed), and the study of possible emissions and microplastics release.

The report details the recycled plastic selection process and its characterisation for bitumen and asphalt applications. In addition, preliminary testing of the shortlisted plastics in combination with bitumen and asphalt to evaluate the performance of the blends and mixtures is provided.

The is the second report from project APT6305. The first examined the use of road-grade recycled plastics in asphalt pavements and investigated the most suitable types of recycled plastics for incorporation into asphalt.

Watch a two-part webinar with authors Dr Filippo Giustozzi, Yeong Jia and Dr Marie Enfrin.

Session 1 details the potential use of road-grade recycled plastics in asphalt pavements and the selection of the most suitable types of recycled plastics for incorporation into asphalt.

Session 2 provides an overview of the outcomes of testing to date including techniques to assess emissions and microplastic release associated with the manufacture, placement and use of asphalt containing recycled plastic.

- 1 Introduction

- 1.1 Study Purpose

- 1.2 Study Scope

- 1.3 Methodology

- 2 Experimental Analysis of Shortlisted Recycled Plastics: A Comprehensive Characterisation

- 2.1 Recycled Plastic Sources Acquired from Australia and New Zealand

- 2.2 The Ranking Strategy

- 2.3 Characterisation of Recycled Plastic Materials

- 2.3.1 Recycling Contamination – Fourier-Transform Infrared (FTIR) Spectroscopy

- 2.3.2 Blendability – Differential Scanning Calorimetry (DSC)

- 2.3.3 Purity – Thermogravimetric Analysis (TGA)

- 2.3.4 Processability – Melt Flow Index (MFI)

- 2.3.5 Storage Stability – Density Analysis

- 2.3.6 Solubility – Hansen Solubility Parameters (HSP)

- 2.3.7 Polarity – Water Contact Angle (WCA)

- 2.3.8 Hazardous Additives – Gas Chromatography/Mass Spectrometry (GC/MS)

- 2.3.9 Wet and Mixed Methods: Summary of the Ranking Criteria

- 2.3.10 Dry Method: Ranking Criteria

- 2.4 Final Ranking Scores

- 2.4.1 Wet and Mixed Methods

- 2.4.2 Dry Method

- 2.5 Sensitivity Analysis

- 2.5.1 Wet and Mixed Methods

- 2.5.2 Dry Method

- 2.5.3 Impact of the Parameters’ Weighting on Plastic Ranking

- 2.6 Selection of Recycled Plastic Type and Source

- 2.6.1 Wet and Mixed Method

- 2.6.2 Dry Method

- 2.7 Conclusion

- 3 Recycling Plastics in Bitumen Through the Wet Method: Preliminary Results Towards Performance-based Specifications

- 3.1 Selected Type of Recycled Plastics and their Characteristics

- 3.2 Materials

- 3.2.1 Bitumen

- 3.2.2 Aggregates

- 3.2.3 Compatibilisers

- 3.3 Recycled Plastic-Modified Bitumen

- 3.3.1 Blending Procedure

- 3.3.2 Testing framework

- 3.4 Recycled Plastic-Modified Asphalt Using the Wet Method

- 3.4.1 Mix design and Optimum Binder Content

- 3.4.2 Asphalt Volumetrics

- 3.4.3 Compactability

- 3.5 Wet Method – Preliminary Results

- 4 Recycling Plastics in Bitumen Through the Dry Method: Preliminary Results Towards Performance-based Specifications

- 4.1 Selected Type of Recycled Plastics and their Characteristics

- 4.2 Materials

- 4.2.1 Bitumen

- 4.2.2 Aggregates

- 4.3 Testing Framework

- 4.4 Recycled Plastic Asphalt Using the Dry Method

- 4.4.1 Mix Design and Optimum Binder Content

- 4.4.2 Asphalt Volumetrics

- 4.4.3 Compactability

- RABS

- RPET

- 4.4.4 Compactability – Interim Conclusions

- 4.5 Dry Method – Preliminary Results

- 5 Potential Emissions from Recycled Plastic-modified Bitumen

- 5.1 Introduction on Emissions from Bitumen and Asphalt

- 5.1.1 Polycyclic Aromatic Hydrocarbons (PAHs)

- 5.1.2 Volatile Organic Compounds (VOCs)

- 5.1.3 Available Standards for Fuming and Emissions Testing

- Measurement of VOCs in Air

- Measurement of PAHs in Air

- Measurement of Total Particulate Matter (TPM) in air

- 5.2 Development of Emissions Testing Framework for Wet and Dry Method

- 5.2.1 Wet Method Testing

- 5.2.2 Mixed and Dry Method Testing

- 5.2.3 Materials

- 5.2.4 Testing Procedure and Sample Preparation

- 5.2.5 Fume Generation and Measurement

- 5.2.6 Analytical Techniques for VOC Analysis

- 5.2.7 Analytical Techniques for PAH Analysis

- 5.2.8 Calculation of TPM Concentration

- 5.2.9 Calibration

- 5.2.10 Testing Variables

- 5.3 Preliminary Results

- 5.4 Emissions – Proposed Assessment Framework

- 5.1 Introduction on Emissions from Bitumen and Asphalt

- 6 Potential Release of Microplastics from Recycled Plastic-modified Asphalt: Development of a Testing Framework

- 6.1 Introduction

- 6.1.1 Environmental Challenges Related to Microplastics

- 6.1.2 Available Standards Assessing Road Abrasion

- 6.1.3 Applicability to Asphalt Materials

- 6.2 Development of a Testing Framework

- 6.2.1 Overall Strategy

- 6.2.2 Materials

- 6.2.3 Instrument

- 6.2.4 Analytical Techniques

- 6.2.5 Method Optimisation

- Abrasion

- Extraction of Microplastics

- Step 1 – Water collection

- Step 2 – Bitumen dissolution

- Step 3 – Density separation of microplastics and aggregates

- Step 4 – Fractionation of microplastics by size-selective filtration

- Validation of the Extraction Method and Application to Road Dust Analysis

- Step 1 – Optimisation of microscope settings

- Step 2 – Optimisation of staining conditions

- Step 3 – Differentiation between microplastics and roadside contaminants

- 6.2.6 Conclusions and Future Work

- 6.1 Introduction

- 7 Overall Interim Conclusions and Future Developments

- Plastics Characterisation

- Wet Method Testing

- Dry Method Testing

- Fume and Emissions Testing

- Microplastic Release and Analysis

- References

- Appendix A Supplementary Figures

- A.1 Identification of Calcium Carbonate in Recycled Plastic

- A.2 Calibration Curves

- A.3 Hansen Solubility Parameters

- A.4 Extraction of Microplastics

- A.5 Advanced Analysis of Microplastics

- Appendix B Suppliers of Recycled Plastic for Report No. 2