3.3.2 Multiple-layer Applications

Sprayed seals may consist of multiple-layer applications of binder and/or aggregate. Some of the most common multiple layer application sprayed seals are described below. Other combinations not described are possible and may be explored by innovative practitioners.

Multiple-application seals provide a robust, heavy-duty surfacing. Examples include haul roads, roads subject to snow clearing operations, and ford crossings of creeks.

Double/double seal

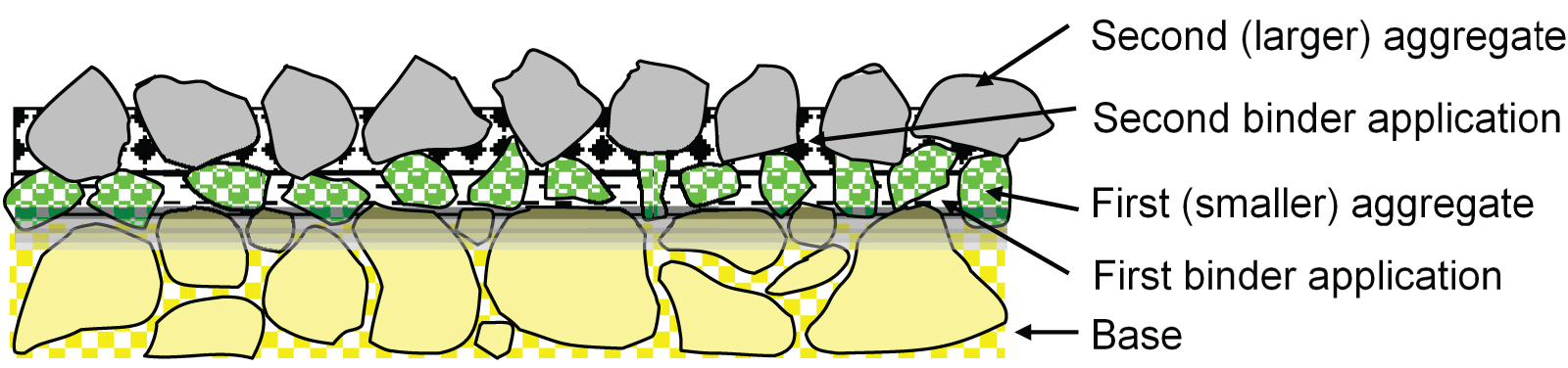

A double/double seal is applied by spraying a layer of binder, spreading the large-sized aggregate and, after suitable rolling and sweeping, spraying another lower application of binder followed by the spreading of a layer of smaller aggregate. The smaller aggregate fits into the spaces between the larger aggregate and locks it into place (Figure 3.5). Double/double seals are commonly described by their aggregate sizes, for example a ‘14/7 double/double’ indicates a 14 mm bottom layer, covered by a 7 mm top layer.

Figure 3.5: Double/double seal

Single/double seal

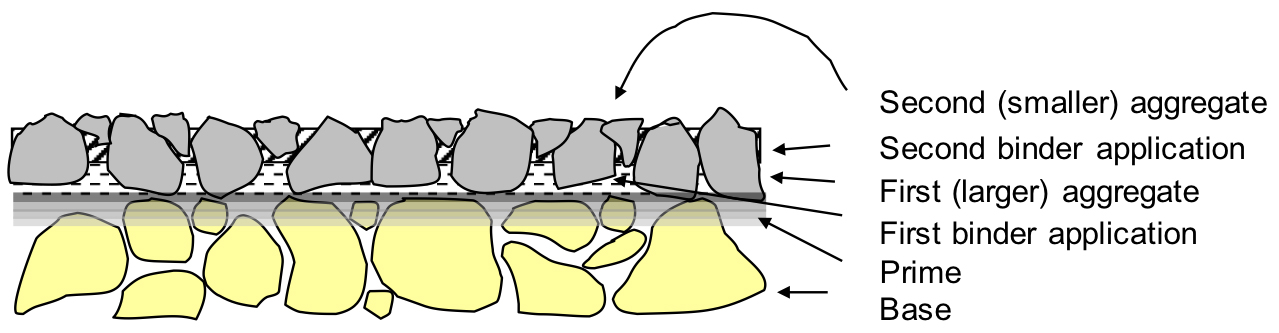

A single/double is a variation of the double/double seal (Figure 3.5). It is constructed by spraying a single layer of bitumen, spreading the large-sized aggregate at a more open spread rate than for a single/single seal and, before rolling is complete, spreading another layer of smaller aggregate. The smaller aggregate fits into the spaces between the larger aggregate and is locked into place by a small amount of bitumen (from the first spray). In a single/double seal, the second aggregate application is a permanent and integral part of the seal.

In New Zealand this type of treatment is also referred to as a ‘racked-in’ chip seal.

Scatter coat

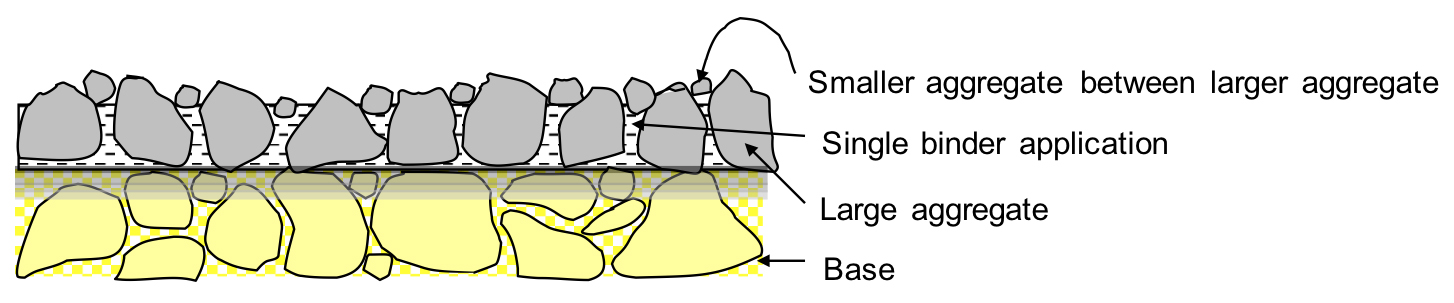

A scatter coat is used in a similar manner to a single/double seal, the difference being that the first application of aggregate is spread at the normal rate for a single/single seal and the second aggregate application, or scatter coat, is used to provide a temporary mechanical interlock between the larger particles. This prevents traffic overturning and dislodging the coarse aggregate particles during the initial curing and compaction of the seal (Figure 3.6).

Figure 3.6: Single/single seal with a scatter coat

A scatter coat is particularly applicable when using emulsions.

A scatter coat differs from a single/double or racked-in seal in that the second aggregate is not applied until after rolling of the first application of aggregate is complete to avoid the small aggregate lodging below, and affecting adhesion of, the larger aggregate. As there is very little binder contact with the second aggregate, it is expected that a significant proportion of the smaller aggregate will be lost during the early service life of the seal as part of the process of further re-orientation of the principal aggregate under the action of traffic.

A scatter coat is similar to the ‘dry lock’ process used in New Zealand although, when used there, it is expected that a significant proportion of the second aggregate will remain wedged between the larger particles, resulting in a different appearance and reduced texture depth compared to a single/single seal.

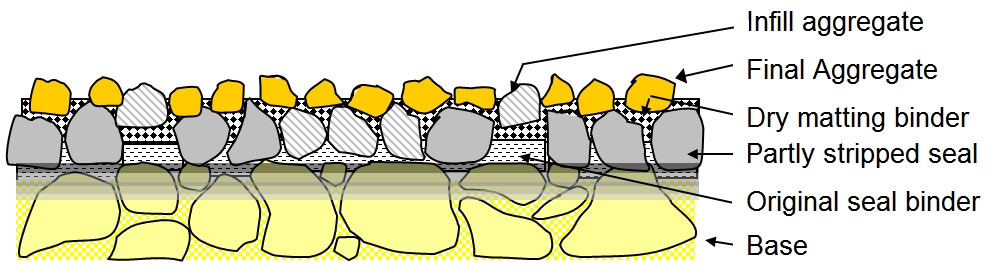

Dry matting

Dry matting (also referred to as a ‘sandwich seal’ in New Zealand) is a technique involving the use of two applications of aggregate sandwiched around a single application of binder.

A particular use of dry matting is as a corrective treatment on stripped or partially stripped seals, or flushed bituminous surfaces. The process involves the spreading of a single layer of aggregate over the existing surface (or infill of the stripped areas of a partially stripped seal (Figure 3.7)) followed by a single application of binder and a further application of aggregate, generally a small-sized aggregate to lock the first aggregate application in place.

Figure 3.7: Dry matting

Inverted seal

An inverted seal (Figure 3.8) is a double/double seal that is ‘inverted’ from the normal double/double seal, such that the smaller-size aggregate is on the bottom coat and the larger-size aggregate is on the top coat. For example, it is a 7/14 rather than a 14/7 seal. Both applications are normally placed on the same day.

An inverted seal can be used to treat surfaces with large variation in transverse surface texture. It may also be used to reduce risk of embedment of the larger aggregate into soft pavement materials.

Figure 3.8: Inverted seal