6.2.3 Embedment Allowance (Ae)

Embedment allowance compensates for loss of voids in the seal under traffic due to the aggregate being forced into of the substrate. This depth of embedment will depend on the volume and mass of traffic and the condition (hardness) of the surface being sealed.

Embedment problems can generally be recognised by the fact that the wheelpaths will become flush in a very short time period (within weeks), while the remainder of the seal remains coarser textured. Long‑term, very slow reduction in texture is a separate issue and not part of this step in the design process.

Embedment on pavement and primes

Embedment of aggregate may occur in initial treatments applied over:

- a soft base

- primed or initial sealed surfaces.

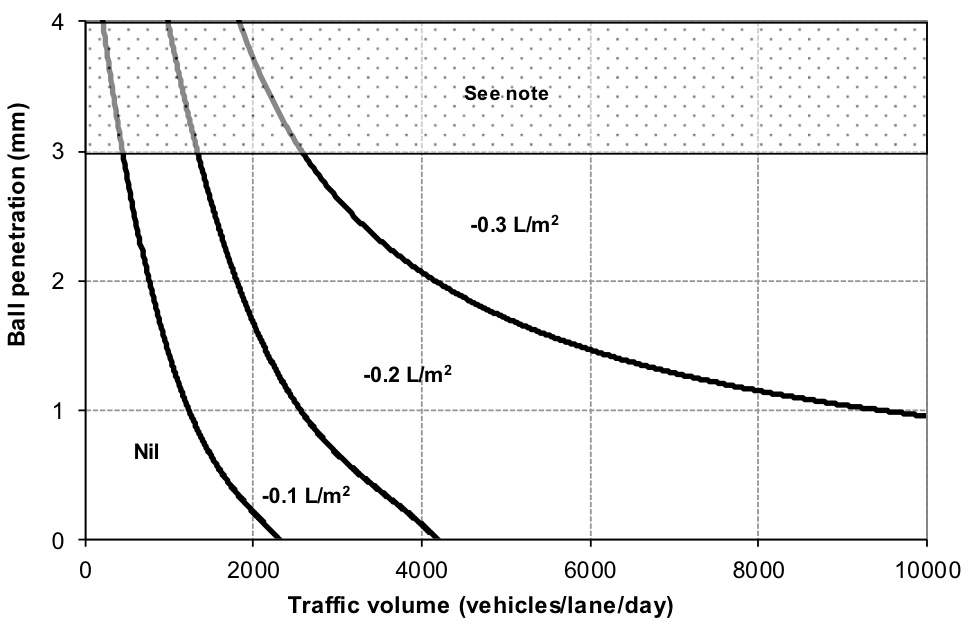

Typical embedment allowances (in L/m2) are shown in Figure 6.5. Pavement surface hardness should be determined in accordance with Austroads (2010c).

Figure 6.5: Embedment allowance for initial treatments

Note: It is recommended that the following alternatives be considered where the ball embedment value exceeds 3 mm:

- If due to moisture, defer sealing to allow the surface to harden as it dries back. The surface should be retested once it has dried sufficiently.

- Apply a small aggregate seal as the first seal to act as an armour-coat and minimise the amount of embedment of the larger aggregate applied at a later date, say after about 12 months. This is only recommended for roads with low traffic volumes with low percentages of heavy vehicles.

To minimise potential risk of flushing/bleeding it is recommended that:

- When cutback bitumen is used, the secondary treatment should not be applied until a reasonable period of curing has elapsed, as residual cutter oil can soften subsequent bituminous surfacings. The curing rate depends on binder grade, application rate and climatic conditions during the curing period. A minimum of six months of warm or hot weather is recommended, although 12 months may be beneficial in colder weather. The minimum curing period may be reduced to three months for relatively low cutter content initial seal binders (such as AMC7) when used in warm or hot conditions.

- A surface primed with cutback bitumen should be allowed to cure for a minimum period of three days prior to sealing. Otherwise, the possibility of absorption of binder and the potential cutting back effect of the cutter in the primer must be taken into consideration. Bitumen emulsion primers (specialty grades) can often be sealed after one or two days curing depending on prevailing drying conditions.

Embedment on reseals

Embedment of aggregate may occur in reseals:

- if there is free binder on the surface being resealed

- when applying a reseal over fresh asphalt or microsurfacing

- when applying a reseal over fresh maintenance patching. Patches that are soft and/or porous can cause problems with embedment and/or binder absorption. Maintenance patches should be allowed to cure for a minimum of three to six months depending on type of patching material (Austroads 2010b).

Where the binder in the existing seal is relatively soft, some embedment may occur. The ball penetration test (Austroads 2010c) has been found to provide poor correlation with field performance for flushed bitumen surfaces and further research is required to determine appropriate allowances. In the meantime, designers must apply their own judgement in providing suitable allowances. Where surfaces are severely flushed, alternative treatments may need to be considered. Alternative treatments may include:

- specialty treatments (Section 4.9)

- surface treatments using solvent and aggregate (Austroads 2010a)

- removal of excess bitumen by high-pressure water blasting (Austroads 2004)

- selection of a surfacing type other than a sprayed seal.